A generating station which converts heat energy of coal combustion into electrical energy is known

as a steam power station.

A steam power station basically works on the Rankine cycle. Steam is produced in the boiler by

utilizing the heat of coal combustion. The steam is then expanded in the prime mover (i.e., steam

turbine) and is condensed in a condenser to be fed into the boiler again. The steam turbine drives the

alternator which converts mechanical energy of the turbine into electrical energy. This type of power

station is suitable where coal and water are available in abundance and a large amount of electric

power is to be generated.

Advantages

(i) The fuel (i.e., coal) used is quite cheap.(ii) Less initial cost as compared to other generating stations.

(iii) It can be installed at any place irrespective of the existence of coal. The coal can be transported

to the site of the plant by rail or road.

(iv) It requires less space as compared to the hydroelectric power station.

(v) The cost of generation is lesser than that of the diesel power station.

Disadvantages

(i) It pollutes the atmosphere due to the production of large amount of smoke and fumes.(ii) It is costlier in running cost as compared to hydroelectric plant.

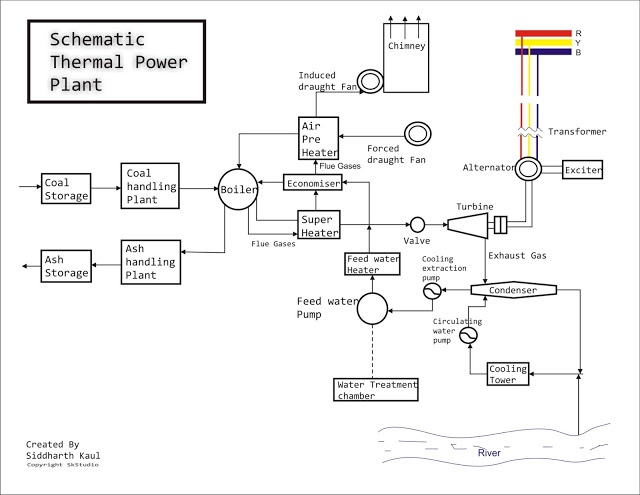

Schematic Arrangement of Steam Power Station

Although steam power station simply involves the conversion of heat of coal combustion into electrical

energy, yet it embraces many arrangements for proper working and efficiency. The schematic

arrangement of a modern steam power station is shown in Fig. 2.1. The whole arrangement can be

divided into the following stages for the sake of simplicity :

1. Coal and ash handling arrangement 2. Steam generating plant

3. Steam turbine 4. Alternator

5. Feed water 6. Cooling arrangement

1. Coal and ash handling plant. The coal is transported to the power station by road or rail and

is stored in the coal storage plant. Storage of coal is primarily a matter of protection against coal

strikes, failure of transportation system and general coal shortages. From the coal storage plant, coal

is delivered to the coal handling plant where it is pulverized (i.e., crushed into small pieces) in order

to increase its surface exposure, thus promoting rapid combustion without using large quantity of

excess air. The pulverized coal is fed to the boiler by belt conveyors. The coal is burnt in the boiler

and the ash produced after the complete combustion of coal is removed to the ash handling plant and

then delivered to the ash storage plant for disposal. The removal of the ash from the boiler furnace is

necessary for proper burning of coal.

It is worthwhile to give a passing reference to the amount of coal burnt and ash produced in a

modern thermal power station. A 100 MW station operating at 50% load factor may burn about

20,000 tons of coal per month and ash produced may be to the tune of 10% to 15% of coal fired i.e.,

2,000 to 3,000 tons. In fact, in a thermal station, about 50% to 60% of the total operating cost

consists of fuel purchasing and its handling.

0 Comments